[ad_1]

In recent years, the demand for digital engineering, rapid prototyping, short-run production, and the DIY electronics movement has driven significant innovations in desktop circuit board manufacturing machines. These machines enable hobbyists, researchers, and small-scale producers to design, iterate, and fabricate circuit boards in-house, drastically reducing the time from concept to working prototype. While the speed of board turnaround is the chief advantage of desktop manufacturing machines, there are many other considerations when choosing such a machine. Cost is a significant driver in that choice, and the machines available for desktop circuit board manufacturing can run from the low thousands to tens of thousands of dollars. Obviously, the cost variances are driven by available features and the underlying technologies of the different classes of machines. In this article, we highlight some of the differences between desktop board manufacturing and traditional manufacturing techniques. We will also explore the different machine categories and digital tools available on the market for desktop circuit board manufacturing.

Desktop Manufacturing versus Factory-based Manufacturing

There are numerous advantages to locally manufacturing circuit boards using desktop machines. There are also drawbacks, of course. Your board layouts will likely need significant changes if they were initially created for traditional circuit board manufacturing infrastructure. Let’s begin by looking at some of the benefits of using desktop machines for circuit board manufacturing.

- Cost-Effective for Prototyping: Instead of outsourcing to large-scale manufacturers, companies and individuals can produce small batches of PCBs at a fraction of the cost.

- Rapid Prototyping: Iteration cycles become much quicker. Designs can be tested and modified in-house without waiting for external manufacturers. With reduced lead time, there’s no need to wait for shipping or deal with potential delays from an external manufacturer.

- Convenience: An on-site machine allows immediate adjustments and reduces the logistical challenges of communicating with third-party manufacturers.

- Learning Opportunity: For educational institutions and hobbyists, these machines provide hands-on experience with PCB manufacturing, fostering a deeper understanding of the process.

- Control Over Intellectual Property: Keeping the prototyping process in-house can protect intellectual property and sensitive designs from potential leaks.

- Customization: Small-scale production allows for greater customization without the constraints often imposed by larger manufacturers.

Of course, every engineering decision comes with both positive and negative consequences. One should be aware of numerous differences and potential negatives when deciding to leverage desktop circuit board manufacturing machines. These include:

- Limited Scalability: Desktop machines are not designed for large-scale production. For bulk manufacturing, larger industrial machines or outsourcing is still necessary.

- Quality Variance: The quality of PCBs produced on desktop machines might not always match those produced by specialized, industrial-grade equipment.

- Material Constraints: Desktop machines might have limitations on the type of materials they can work with or may not be optimized for all types of PCB materials. Single- and double-sided copper-clad boards FR-1 and FR-4 are the most common for entry-level machines.

- Maintenance: Like all machinery, desktop PCB machines require regular maintenance, which can be time-consuming and require specialized knowledge.

- Space Requirements: Although designed for desktop use, these machines still occupy space and might require specific environmental conditions to operate optimally.

- Initial Investment: Despite being cost-effective in the long run, purchasing the machine has a considerable upfront cost.

- Skill Requirement: The machine’s proper operation, maintenance, and troubleshooting require training and experience.

- Limited Features: Depending on the model, some desktop machines might not support advanced features like multi-layer PCB production, fine-pitch components, or advanced surface finishes.

Digital Engineering Tools Available for Desktop Circuit Board Manufacturing

Several types of engineering tools are suitable for desktop circuit board manufacturing. Understanding their nuances is necessary to pick a machine that meets your needs and financial capability. Let’s take a look at some of the most common digital engineering tools used for desktop circuit board manufacturing.

Milling Machines

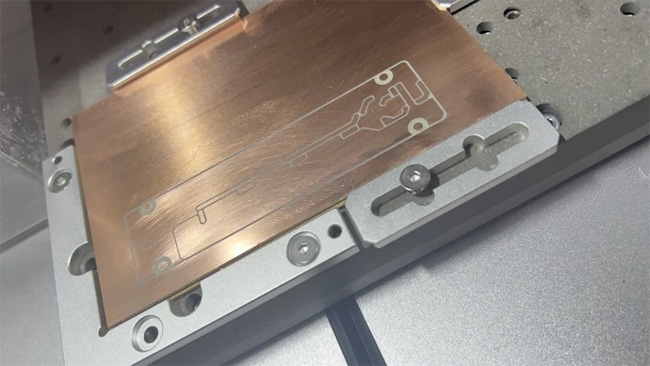

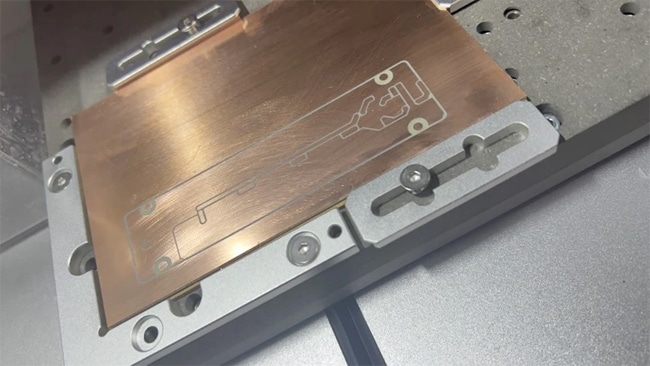

Milling machines use rotary cutting bits to remove material from a PCB blank to produce circuit tracks. Some of the most popular PCB milling machines for desktop use include the Bantam Tools (formerly OtherMill) desktop CNC milling machine and the Makera Carvera. These are fast and reliable machines ideal for producing circuit boards, and these two particular manufacturers make user-friendly machines that can mill PCBs down to very fine traces, making them suitable for SMD components. Typically, copper-clad FR-1 and FR-4 boards are used for milling operations. Negatively, milling consumes more material due to the subtractive nature of the process. Milling can also be noisy and produce debris.

PCB Printers

In contrast to the subtractive nature of milling machines, circuit board printers adopt an additive approach, depositing conductive ink onto a substrate to create circuit patterns. Popular machines on the market include the Voltera V-One, which not only prints PCBs but can also dispense solder paste and reflow components, making it a comprehensive desktop PCB production solution. The BotFactory Squink is another innovative PCB printer that, in addition to printing circuits, can also place components and cure the ink, enabling complete board production on the desktop. The main benefit of PCB printers is they are fairly clean, with very little debris created during production. The particular machines mentioned here offer additional features to make them nearly one-stop shops for low-volume PCB manufacturing. One of the shortcomings of PCB printers is the fact that the conductive inks might not be as robust as traditional, etched copper. Also, traces and pads might be limited to larger sizes due to the resolution of the print head, which can make printers ill-suited for very fine pitch components.

Laser Etchers and Cutters

Another class of CNC machines includes laser etchers and cutters. While laser cutters may not be purpose-built for PCB manufacturing, they can be used to either etch away unwanted copper from a PCB or cut the PCB material itself. Recent advancements in laser technologies are pushing down costs, and combined with their highly detailed precision, lasers are gaining popularity for PCB production. Laser cutters are increasingly finding their way onto workshop benches and can create very fine details that are perfect for making circuit boards. Companies such as LPKF Laser & Electronics and Glowforge offer a range of laser-based PCB prototyping machines suitable for various applications, from simple PCBs to RF circuits. The chief advantage of laser technology is the high precision with clean edges. This is fantastic for very fine-pitched components and traces. Additionally, lasers are suitable for both etching and cutting tasks. Countering the positive aspects of laser cutters are the obvious safety concerns that arise when using a laser. It requires HEPA-grade filters to quickly and safely extract fumes from the cutting volume. Laser cutters are susceptible to the smoke generated by the etching process and can have a negative impact on quality. Lastly, laser cutters, especially high-wattage cutters, can be more expensive compared to other methods.

Complete Desktop PCB Production Systems

Making PCBs is just one part of the battle. Electronic components must be attached to the circuit board to realize a working system, resulting in an assembled printed circuit board (PCBA). In addition to the PCB manufacturing hardware, reflow ovens and pick-and-place machines are additional equipment required to go from PCB to PCBA. Some companies, such as Neoden, offer machines with a comprehensive PCBA solution that integrates multiple stages of the circuit board production process. Nedoen offers a family of desktop products for low-volume yet professional PCBA manufacturing. The Neoden FP2636 stencil printers provide a reliable and repeatable mechanism to apply solder to PCBs. The Neoden YY1 is a desktop pick-and-place for moving components from reels to the PCB. Lastly, the Neoden IN6 offers reflow soldering. Combined, these machines are ideal for those who want to go beyond just producing PCBs and move into complete board assembly. While these machines are one-stop solutions that streamline the manufacturing process, they are not entirely out of the realm of professional and serious makers, as they cost only a few thousand dollars. However, they do stretch the definition of desktop manufacturing since they tend to require a larger footprint both physically and electrically.

Conclusion

The rise in desktop circuit board manufacturing machines has democratized access to PCB prototyping and production. Depending on the specific requirements—be it precision, speed, versatility, or the nature of production (subtractive vs. additive)—there’s likely a machine tailored to those needs. As technology advances, we can anticipate further improvements in speed, affordability, and capabilities, ensuring that in-house PCB production remains accessible to all.

Michael Parks, P.E. is the co-founder of Green Shoe Garage, a custom electronics design studio and embedded security research firm located in Western Maryland. He produces the Gears of Resistance Podcast to help raise public awareness of technical and scientific matters. Michael is also a licensed Professional Engineer in the state of Maryland and holds a Master’s degree in systems engineering from Johns Hopkins University.

[ad_2]

Source link